GENERAL MANAGEMENT

CHECK POINT 4: LEAN MANAGEMENT

Please Select Any Topic In Check Point 4 Below And Click. |

|

|

| |

|

DO I NEED TO KNOW THIS CHECK POINT?

|

| |

WELCOME TO CHECK POINT 4 |

|

| |

HOW CAN YOU BENEFIT FROM CHECK POINT 4? |

| |

| The main purpose of this check point is to provide you and your management team with detailed information about Lean Management values, principles, methods, and guidelines and how to apply this information to maximize your company's performance. |

| |

| In this check point you will learn: |

| |

• About the purpose and basic advantages of lean management.

• About the origin of lean management and the Toyota Production System.

• About basic lean management values, principles, and guidelines.

• About value-added and non-value-added operational activities and three types of waste.

• How to complete your company's lean transformation process.

• How to create a lean management team and create lean team managers.

• How to identify what you customers want and develop the best value proposition.

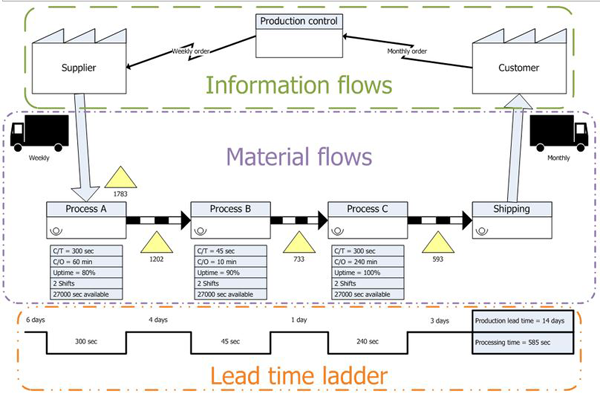

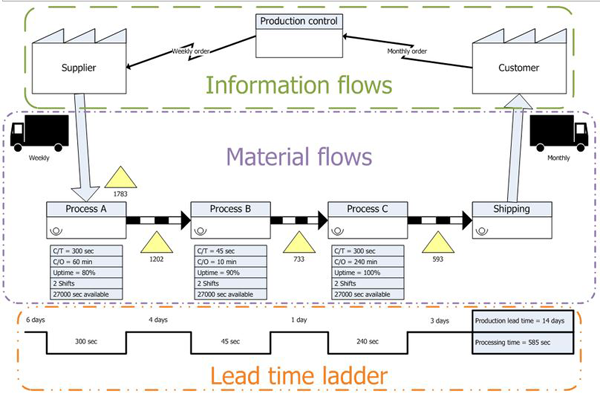

• How to complete value-stream mapping and value-added analysis.

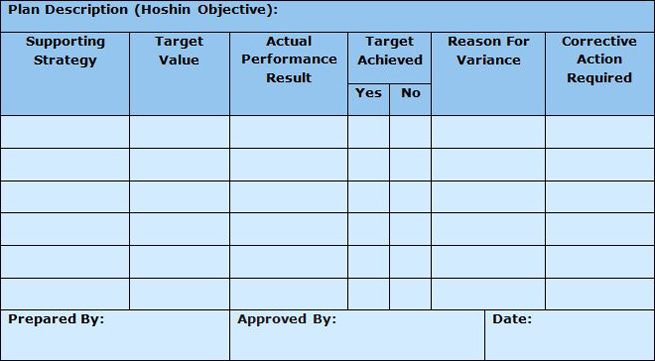

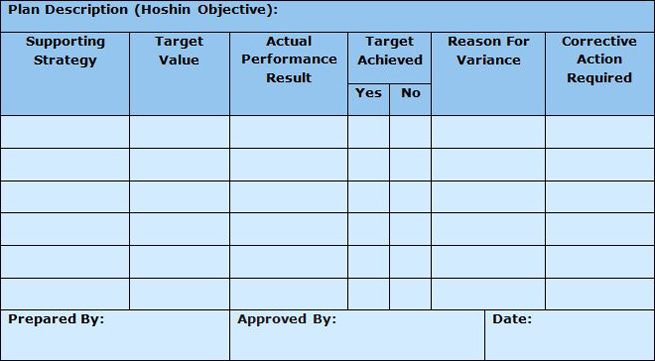

• How to develop and implement hoshin planning.

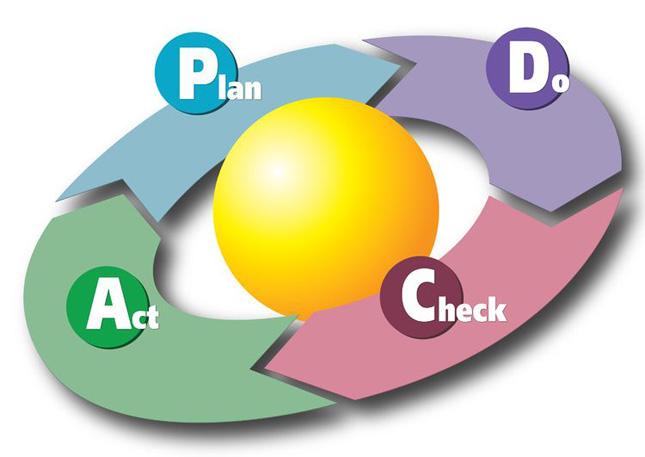

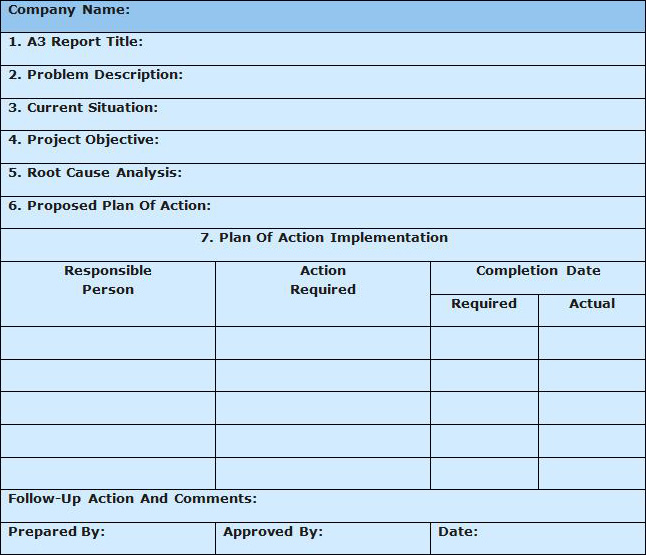

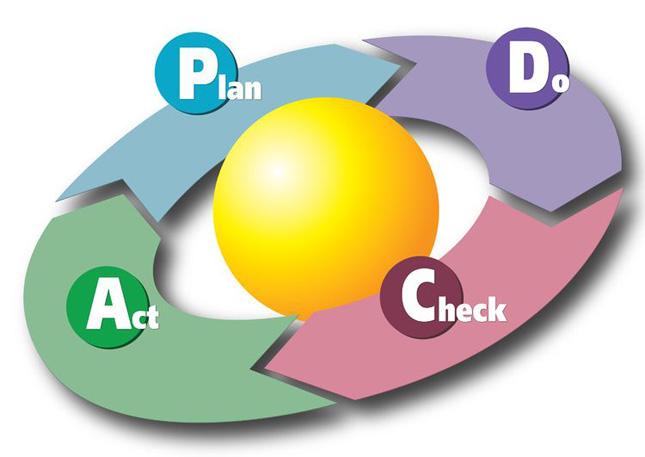

• How to implement kaizen, PDCA cycle, just-in-time, jidoka... and much more. |

| |

LEAN MANAGEMENT GUIDELINES FOR CHECK POINT 4 |

| |

| You and your management team should become familiar with the basic Lean Management principles, guidelines, and tools provided in this program and apply them appropriately to the content of this check point. |

| |

| You and your team should adhere to basic lean management guidelines on a continuous basis: |

| |

| • |

Treat your customers as the most important part of your business. |

| • |

Provide your customers with the best possible value of products and services. |

| • |

Meet your customers' requirements with a positive energy on a timely basis. |

| • |

Provide your customers with consistent and reliable after-sales service. |

| • |

Treat your customers, employees, suppliers, and business associates with genuine respect. |

| • |

Identify your company's operational weaknesses, non-value-added activities, and waste. |

| • |

Implement the process of continuous improvements on organization-wide basis. |

| • |

Eliminate or minimize your company's non-value-added activities and waste. |

| • |

Streamline your company's operational processes and maximize overall flow efficiency. |

| • |

Reduce your company's operational costs in all areas of business activities. |

| • |

Maximize the quality at the source of all operational processes and activities. |

| • |

Ensure regular evaluation of your employees' performance and required level of knowledge. |

| • |

Implement fair compensation of your employees based on their overall performance. |

| • |

Motivate your partners and employees to adhere to high ethical standards of behavior. |

| • |

Maximize safety for your customers, employees, suppliers, and business associates. |

| • |

Provide opportunities for a continuous professional growth of partners and employees. |

| • |

Pay attention to "how" positive results are achieved and constantly try to improve them. |

| • |

Cultivate long-term relationships with your customers, suppliers, employees, and business associates. |

|

|

|

1. WHAT IS LEAN? |

|

|

INTRODUCTION TO LEAN |

You and your management team should become fully familiar with lean management concepts, methods, and guidelines if you really want to secure your long-term success in business.

What goes through your mind when somebody says: "Rolls Royce"? You probably think: It's the ultimate super-expensive luxury car. And what goes through your mind when somebody says: "This product is made in Japan". You probably think:

I expect this product to provide high value based on quality, reliability, and price. If I need this type of product, I will strongly consider spending more money and purchasing a Japanese-manufactured product instead of trying to "save" money and taking a chance.

If you realize that millions of consumers worldwide also feel very strong about the "Made in Japan" brand, you will appreciate the real power of Lean!

Lean* embodies some of the best management concepts, principles, methods, and values which are critical in developing an effective business organization and improving every aspect of its performance on a continuous basis. Lean has practical applications in all areas of operational activities and it can be used by a one-person business owner or by any type of small, medium-sized, and large business organization.

* Note:

A large part of information about Lean in this check point is based on management concepts, principles, guidelines, methods, and tools developed over a sixty-plus-year period by management experts in the Toyota Motor Corporation in Japan and contained in the Toyota Production System. |

|

WHAT IS REALLY SO SPECIAL ABOUT LEAN?

|

1. |

Lean Is A Universal Management Tool.

Lean is a universal management tool applicable to various types of small, medium-sized, and large business organizations. Although lean was developed in a large-scale manufacturing environment in Japan, it is equally useful in every manufacturing and non-manufacturing organization anywhere in the world. Lean can be applied effectively in a service, merchandising, contracting, or project management organization of any size. |

2. |

Lean Is A Comprehensive Management Methodology.

Lean can be applied to all operational management functions and activities within any business. This means that lean can be used very effectively in general administration, human resources, finance and accounting, operations, marketing and sales management activities. |

3. |

Lean Provides Practical Management Guidelines.

Lean has been successfully tested by many business owners and managers who aim to maximize their organization's operational performance and profitability. Lean really works and, if you give it a chance, it will help you to turn your company around and make it more profitable in the long term. |

4. |

Lean Makes Good Business Sense.

Lean will enable you to focus on what is really important in your business, namely: providing the best value of products and services to your customers and in return to receive their continued long-term loyalty and support. Ultimately, this will pay your bills and maximize your profits. |

5. |

Lean Represents A Strong And Positive Business Culture.

Lean will guide you and your management team in adopting meaningful and ethical principles of business behavior which will subsequently result in increased productivity, improved profitability, and higher return on your investment. Once you will embark on the lean journey, you will never want to stop it! |

6. |

Lean Business Engineering Provides The Ultimate Business Management Solution.

Lean fits perfectly well with another unique business management methodology introduced in this program, called Business Engineering. The Business Engineering Method is based on a comprehensive multi-disciplinary approach to business management and covers all major elements of operational business activities. Once you realize the full potential of both methodologies, you will be ready to implement Lean Business Engineering in your organization. |

|

| |

Note:

Since lean represents an organization-wide management methodology applicable to all operational activities and not limited only to operations management, it is presented in Tutorial 1. |

| |

THE MAIN PURPOSE OF LEAN MANAGEMENT |

| The main purpose of lean management is to maximize the company's performance by providing customers with a perfect value of products and services and developing a perfect value-creation process that has zero or minimal waste. |

Lean Management is designed to maximize the all-around operational performance and profitability of any business organization by offering the best possible value of products and services, based on quality, reliability, and price, to its customers* while minimizing waste and using fewer resources.

Lean management is a practical management tool which will enable you and your management to transform your organization into "lean organization" and implement "lean principles and values" in the most cost-effective manner.

Lean management methods are quite different from the traditional "Western-style" business management methods which you may be using at present. However, once you decide to implement these methods, you will be surprised, how they can help your organization to become more efficient and profitable. For this reason, you should become familiar with lean management methods, adopt lean values, principles, and guidelines and get ready to transform your business organization into a

Lean Organization.

* Note:

In this program the term "customer" means the ultimate consumer of products and services or a business entity that purchases products and services for resale to other customers. |

| |

MAKE YOUR CUSTOMERS HAPPY AND THEY WILL MAKE YOU HAPPY TOO! |

Peter F. Drucker, one of the fathers of the Modern Management Science, stated that:

"The purpose of a business is to create a customer"

Business owners and managers in a lean organization are strong believers that:

The customer is the most important part in the business process and all efforts should be made to ensure that every customer receives maximum value, based on best possible quality, reliability, and price.

Moreover, it will be wise to remember two basic rules when dealing with customers:

• Rule No. 1: The customer is always right!

• Rule No. 2: When the customer is wrong - use Rule No. 1! |

| |

BASIC LEAN MANAGEMENT THINKING |

Business owners and managers in a lean organization understand that their "ticket to business success" is to identify what their customers really want and to provide them with the best possible value to meet their specific needs. The ultimate goal of lean management is to ensure customer satisfaction on a continuous basis, which in turn will provide the foundation for a long-term "win-win" relationship between the organization and its customers.

According to Basic Lean Thinking, business owners and managers must focus on the entire operational process from start to finish, instead of focusing on specific operational activities. This includes everything, namely: general administration, human resources, finance and accounting, operations, marketing and sales. |

| |

LEAN APPLIES TO ALL OPERATIONAL

ACTIVITIES IN EVERY BUSINESS ORGANIZATION |

|

| |

A CHAIN IS ONLY AS STRONG AS ITS WEAKEST LINK |

The entire business process should be viewed as a Chain Of Operational Activities in every organization and, as you know, the "chain is only as strong as its weakest link". For this reason, it is essential to evaluate each operational activity ("operational link") within the lean organization and develop a cost-effective plan to maximize all value-added operational activities ("strong links") and eliminate or minimize all non-value-added operational activities ("weak links") defined as waste. This will subsequently enable the organization to offer the best possible value of products and services to customers and to be profitable at the same time.

In a lean organization, all operational activities are classified in three categories as shown below. |

| |

CLASSIFICATION OF OPERATIONAL ACTIVITIES IN A LEAN ORGANIZATION |

|

|

|

Value-Added

Activities

|

Essential

Non-Value-Added

Activities

|

Unnecessary

Non-Value-Added

Activities |

| This includes all operational activities that add value to the final product or service offered to customers. All value-added operational activities are considered essential in maximizing the organization's ability to offer best possible value to customers. These activities should be evaluated and streamlined for maximum performance and results. |

This includes all operational activities that don't add value to the final product or service offered to customers, but are essential in enabling the organization to meet its specific operational objectives (general administration, human resources, finance and accounting, marketing and sales). These activities should be evaluated and optimized for maximum performance and results. |

This includes all operational activities that don't add value to the final product or service, offered to customers, and considered waste. These activities should be identified and eliminated or reduced for maximum performance and results. |

|

|

|

|

| |

A CONTINUOUS FLOW |

In a lean organization, all operational activities in the business process must create a Continuous Flow like a water stream in a river or a conveyor belt in a factory. Moreover:

• Each operational activity in the continuous flow must add value to the product or service.

• Non-value added operational activities, considered waste, are unacceptable in a

lean organization.

All non-value-added operational activities, defective work, unnecessary documentation, excessive inventory, waiting time, delays, and overspending are considered waste and must be eliminated or minimized to ensure a smooth and continuous operational flow within the organization. This will be critical in enabling the company to provide customers with the best possible product or service value, based on quality, reliability, and price. |

| |

COST-EFFECTIVE VALUE-ADDED STREAMS |

| Lean management prescribes development of Cost-Effective Value-Added Streams throughout the entire operational cycle, which starts with suppliers, proceed within the organization, and end with customers. The main idea behind developing most cost-effective value-added streams is: |

| • |

To maximize quality of products and services. |

| • |

To minimize operational defects. |

| • |

To minimize waste in human resources. |

| • |

To minimize waste of materials. |

| • |

To minimize waste of plant and equipment capacity. |

| • |

To minimize inventory levels. |

| • |

To minimize time to produce products and services. |

| • |

To minimize costs to produce products and services. |

| • |

To minimize facility space requirements. |

| • |

To minimize capital requirements. |

| • |

To maximize operational efficiency and productivity. |

| • |

To maximize profitability and return on investment. |

|

By identifying and eliminating, or minimizing, waste throughout various operational activities, the organization will require less materials, less human resources, less plant and equipment to produce better-quality products and services at reduced costs. This will subsequently reduce capital investment requirements, increase profitability, and improve return on investment.

Although lean methodology finds its origin in large-scale manufacturing environment, lean management principles and guidelines apply equally to all operational activities in small, medium-sized and large manufacturing and non-manufacturing organizations alike.

You must remember that lean is not just a series of practical management principles, methods, and guidelines, but a smart way of thinking and acting within your own business. |

| |

ADDITIONAL INFORMATION ONLINE |

|

|

|

2. THE ORIGIN OF LEAN |

|

|

LEAN TIMELINE |

|

According to Lean Timeline developed by Lean Enterprise Institute, the first "lean activities" took place in the 15th century, when Venetian Arsenal introduced the floating assembly line for boats of standard design. Lean activities continued in different forms throughout the latter centuries and provided foundation for development of lean management concepts in the 20th century.

Modern lean management has its origin with Toyota Production System (TPS) and it has evolved gradually over the last sixty-plus years. This system has been widely used by Toyota and other Japanese manufacturing companies during the second half of the 20th century. The TPS also included several important Japanese management concepts and methods, such as Kaizen, Just-In-Time, Jidoka, and Total Productive Maintenance (TPM). These methods helped many Japanese companies to earn a well-deserved reputation of "high quality and reliability product manufacturers".

"MADE IN JAPAN" BRAND

Many Japanese products became very popular all over the world during the last sixty years because of their high quality and reliability, reasonable price, and high level of customer satisfaction. These products created a universal "Made in Japan" brand in the minds of millions of consumers worldwide. Best examples of this brand include such famous names as:

• Toyota, Honda, Nissan, Subaru, Mazda, and Mitsubishi.

• Sony, Panasonic, Sanyo, Toshiba, Canon, Nikon, Sharp, Hitachi and Fujitsu.

INTRODUCTION OF TERM "LEAN"

During the 1980's several U.S. experts conducted extensive studies of Japanese manufacturing methods with an objective to identify the "secret Japanese manufacturing weapons". One such study was undertaken by a group of researchers at the Massachusetts Institute of Technology (MIT) led by

Dr. James P. Womak.

The term "Lean" was first introduced by John Krafcik in his 1988 article, "Triumph Of The Lean Production System", based on his master's thesis at MIT. Initially, this term applied exclusively to manufacturing processes in a large scale production environment. However, later lean concepts, methods and tools have been expanded to cover a broad range of manufacturing and non-manufacturing processes alike in companies of all sizes.

Today lean is the symbol of "how to do things right at the right price" and provide high quality products and services to customers in the most cost-efficient manner. For this reason you owe it to yourself to study lean management principles to ensure the long-term success of your business. |

| |

ADDITIONAL INFORMATION ONLINE |

|

| |

COMMONLY USED LEAN TERMINOLOGY (SOURCE: WIKIPEDIA) |

Japanese Term |

English Translation |

| Andon |

行灯 |

Signboard. |

| Chaku-Chaku |

着うた |

Load-load. |

| Gemba |

現場 |

Go to where all activities are taking place. |

| Genchi Genbutsu |

現地現物 |

Go and see for yourself. |

| Genjitsu |

実際の事実を集め |

Gather the actual facts. |

| Hansei |

反省 |

Self-reflection. |

| Heijunka |

平準化 |

Production smoothing. |

| Hoshin Kanri |

方針管理 |

Direction management. |

| Jidoka |

自働化 |

Autonomation - automation with human intelligence. |

| Just In Time |

ジャストインタイム |

Just in time (JIT). |

| Kaikaku |

改革, 革新, 根本的な変 |

Reform, radical change, innovation. |

| Kaizen |

改善 |

Continuous improvement. |

| Kanban |

看板, also かんばん |

Sign, index card. |

Manufacturing

Supermarket |

製造スーパーマーケ |

Place where all components are available to be withdrawn by a process. |

| Muda |

無駄, also ムダ |

Waste. |

| Mura |

斑 or ムラ |

Unevenness. |

| Muri |

無理 |

Overburden. |

| Nemawashi |

根回し |

Laying the groundwork, building consensus, literally: Going around the roots. |

| Obeya |

大部屋, also 作戦指令室 |

Large room, war room. |

| Poka-Yoke |

ポカヨケ |

Fail-safe - to avoid (yokeru) inadvertent errors (poka). |

| Seiri |

整理 |

Sort out, organize. |

| Seiton |

整理 |

Straighten, tidy-up. |

| Seiso |

清掃 |

Clean, shine. |

| Seiketsu |

清潔 |

Sanitize, standardize. |

| Shitsuke |

躾 |

Sustain, discipline. |

|

| |

ADDITIONAL INFORMATION ONLINE |

|

|

|

|

3. THE TOYOTA PRODUCTION SYSTEM |

|

|

THE TOYOTA PRODUCTION SYSTEM |

The Toyota Production System (TPS) represents the foundation of Lean Manufacturing, which evolved into Lean Management during the last seven decades and became applicable to a broad range of small, medium-sized, and large organizations. Today, lean management is equally important to manufacturing and non-manufacturing companies alike.

The Toyota Production System was developed by Kiichiro Toyoda and his team in Toyota Motor Corporation during the 20th century and its main purpose has been "the complete elimination of all waste" in pursuit of the most efficient manufacturing methods. This production control system has been developed and continuously improved since 1950’s with the main objective of "manufacturing vehicles ordered by customers in the quickest and most efficient way, in order to deliver the vehicles as quickly as possible."

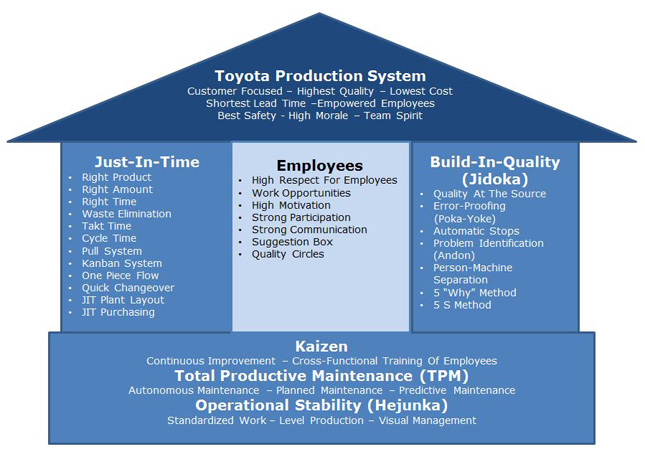

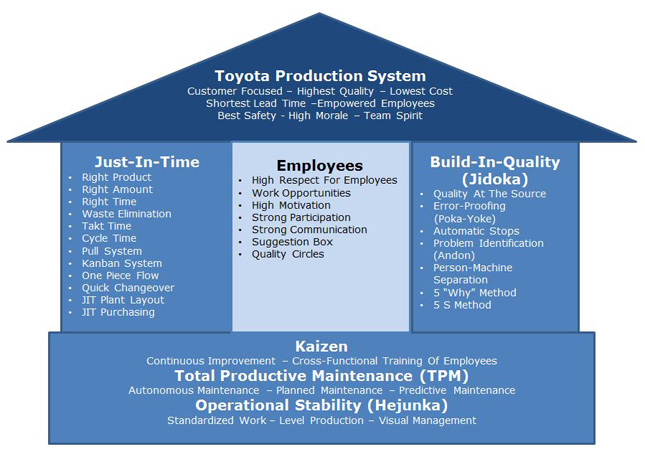

The Toyota Production System is based on several well-known Japanese management methodologies, including Kaizen, Just-In-Time, Jidoka, and Total Productive Maintenance (TPM) introduced below. |

MAIN PILLARS OF THE TOYOTA PRODUCTION SYSTEM |

|

| |

KAIZEN |

The word ”Kaizen” means “good change” or "improvement" in Japanese. Kaizen prescribes “continuous improvement in personal life, home life, social life, and work life”.

According to Masaaki Imai, the father of Continuous Improvement and a pioneer who introduced Kaizen Philosophy all over the world, Kaizen is the single most important concept in Japanese Management and the key to Japanese competitive success. When applied to the workplace, kaizen means continuous improvement of everything by everyone - managers and workers alike.

Kaizen may be a short word, but it represents a very deep and strong culture - a culture of continuous all-around improvement of everything and everywhere. Kaizen is one of the most commonly used words in Japan. As a concept, kaizen is totally ingrained in the minds of Japanese people who "think and breathe" kaizen without realizing it. Many successful Japanese companies adopted kaizen strategy and values as their basic approach to business management.

According to Masaaki Imai, Western business people have been asking for many years how did the Japanese companies achieve such a phenomenal success. Well, the secret is out - and its name is kaizen!

Implementation of kaizen is discussed in this check point. Kaizen is also discussed in detail in Tutorial 4. |

JUST-IN-TIME (JIT) METHODOLOGY |

Just-In-Time represents a “methodology for eliminating or minimizing waste in the total operational process from purchasing through distribution”.

The main purpose of Just-In-Time Methodology, or JIT Methodology, is “ making only what is needed, when it is needed, and in the amount needed!" The JIT methodology was envisioned by Kiichiro Toyoda, the president of Toyota Corporation between 1941 and 1950, and developed by Taiichi Ohno, who is considered the father of Toyota Production System, in 1950’s.

Based on JIT methodology, each process must produce only what is needed “just-in-time” by the next process in a continuous flow environment. JIT methodology prescribes manufacturing high quality products efficiently through the complete elimination of waste, inconsistencies, and unnecessary requirements in the production flow.

Although just-in-time originated in a manufacturing environment, it became widely applicable to manufacturing and non-manufacturing organizations alike including service, merchandizing (retail and wholesale), contracting, and project management companies.

Implementation of Just-In-Time is discussed in this check point. Just-In-Time is also discussed in detail in Tutorial 4. |

JIDOKA |

The word Jidoka is loosely translated from Japanese as "automation with a human touch".

Jidoka means that “when a problem occurs in any process, the equipment must be stopped immediately, thereby preventing defective products from being produced”. This in turn will help maximizing high level of quality and minimizing waste. According to jidoka principles, "quality must be built in during the manufacturing process!"

The basic concept of jidoka was originated by Sakichi Toyoda, the founder of Toyota Corporation, in the beginning of the 20th century. The main purpose of jidoka is to maximize visualization of problems in any manufacturing process. This will help in preventing the production of defective products and result in securing high level of product quality.

Based on jidoka guidelines, if an equipment malfunction or a defective part is discovered, the affected machine must stop automatically, and operators must cease production and correct the problem as soon as possible. Jidoka is critical in the implementation of the just-in-time methodology, whereby all manufactured parts must meet pre-determined quality standards to ensure zero defects.

Implementation of Jidoka is discussed in detail in this check point. |

TOTAL PRODUCTIVE MAINTENANCE (TPM) |

The prime purpose of Total Productive Maintenance (TPM) is to maximize the overall efficiency of equipment and tooling used in the product and service production processes and to minimize operational losses due to equipment and tooling failure.

Since different types of equipment and tools may be used in various manufacturing and non-manufacturing companies, TPM represents a critical function designed to enable any organization to provide the best possible value of products and services to customers at the best possible price.

The traditional TPM program was developed in Japan in 1960’s and it is based on the ”5S” Methodology, which became an integral part of Toyota Production System. The ”5 S” methodology was developed by Hiroyuki Hirano as a part of his overall approach to production systems. This methodology consists of five stages, termed in Japanese as:

|

| 1. |

Seiri - Seiri Sort out all tools and materials and eliminate all unnecessary items in the workplace. |

| 2. |

Seiton - Seiton Straighten or arrange all work, tools, and materials to create an efficient work flow. |

| 3. |

Seiso - Seiso Shine or systematic cleaning of workspace, equipment, and tools. |

| 4. |

Seiketsu - Seiketsu Standardize all operational procedures and tool setups in the workplace. |

| 5. |

Shitsuke - Shitsuke Sustain or ensure continuous adherence to rules and procedures in the workplace. |

|

The main objective of the "5 S" methodology is to provide basic guidelines to operators for organizing their tools and equipment in the workspace to ensure maximum efficiency and productivity in the operational facility.

The TPM program also contains several important elements, or TPM Pillars, including autonomous maintenance, planned maintenance, quality maintenance, focused maintenance, predictive maintenance, training and education, and safety procedures.

Implementation of Total Productive Maintenance is discussed in detail in this check point. |

THE TPS HOUSE |

Toyota developed a graphic representation of Toyota Production System and summarized all main elements of this system in a model TPS House presented below. Hopefully, this will help you to better understand the essence of the Toyota Production System and the basic concepts of lean management. |

|

Source: Adapted from Toyota Corporation. All rights reserved. |

ADDITIONAL INFORMATION ONLINE |

|

|

|

4. BASIC LEAN MANAGEMENT VALUES, PRINCIPLES, AND GUIDELINES |

|

|

THE MAIN FOCUS OF LEAN MANAGEMENT

The main focus of Lean Management is:

To improve the overall performance and profitability of any organization by providing maximum value to customers based on best possible product and service quality, reliability, price, warranty, and after-sales service while minimizing waste.

You and your management team must follow lean management guidelines to identify, evaluate, and improve all operational activities within your organization on a continuous basis, including general administration, human resources, finance and accounting, operations, marketing and sales. This will enable your company to offer the best possible value of products or services to your customers and ensure their high level of satisfaction. Ultimately, this will provide your organization with the best long-term opportunity for a successful business performance in a highly competitive marketplace. |

|

LEAN ENTAILS EVALUATION AND IMPROVEMENT OF ALL OPERATIONAL ACTIVITIES |

|

| |

Lean management process is based on several Lean Management Guidelines outlined below. |

BASIC LEAN MANAGEMENT VALUES AND GUIDELINES |

| 1. |

Treating Each Customer As The Most Important Part Of The Business.

Adopting a philosophy that customers are always the most important part of every business process and must be treated accordingly. |

| 2. |

Providing Each Customer With The Best Possible Value.

Maintaining focus on providing the best possible value of products and services and after-sales service and product support to customers on a continuous basis. |

| 3. |

Meeting Customers’ Requirements At The “Right Time” And “At The Right Price”.

Ensuring that customers’ requirements are met at the “right time” and the “right price” on a continuous basis. |

| 4. |

Respecting All People Involved In The Business Process.

Providing maximum care, dignity, and respect to all people involved in the business process, including customers, employees, suppliers, business partners and associates on a continuous basis. |

| 5. |

Identifying Operational Weaknesses And Taking Corrective Measures.

Identifying weaknesses in various operational processes within the organization and taking corrective measures in a timely manner on a continuous basis. |

| 6. |

Ensuring Continuous Operational Performance Evaluation And Improvement.

Adopting a philosophy of operational performance evaluation and improvement within the organization on a continuous basis. |

| 7. |

Streamlining Operational Processes, Maximizing Efficiency, And Eliminating Or Minimizing Waste.

Streamlining various operational processes, maximizing efficiency, and eliminating or minimizing waste within the organization on continuous basis. |

| 8. |

Maximizing Quality At The Source Of All Operational Processes And Activities.

Ensuring highest level of quality at the source of each operational process and activity within the organization. |

| 9. |

Implementing Operational Process Improvements On Organization-Wide Basis.

Ensuring that operational process improvements take place on organization-wide basis and involve all business partners, employees, and suppliers on continuous basis. |

| 10. |

Ensuring Continuous Personal Self-Evaluation And Improvement.

Adopting a philosophy of regular personal self-evaluation, learning, and self-improvement on a continuous basis. |

| 11. |

Motivating All Employees To Adhere To High Ethical Standards Of Behavior.

Ensuring that all employees adhere to the highest level of ethical behavior throughout all operational activities and interaction with other employees, customers, and suppliers. |

| 12. |

Compensating Employees Fairly Based On Their Performance.

Providing fair reward, compensation, and acknowledgement to all employees, based on their performance within the organization. |

| 13. |

Ensuring Maximum Safety For All Customers And Employees.

Ensuring highest level of safety for all customers and employees related to all operational processes and activities within the organization. |

| 14. |

Ensuring Continuous Professional Growth Of Partners And Employees.

Ensuring that all business partners and employees have the opportunity to grow and improve their performance within the organization on a continuous basis. |

| 15. |

Paying Attention To “How” Positive Results Are Achieved.

Leading the organization toward superior performance and results while paying attention to “how” these results are achieved on a continuous basis. |

| 16. |

Cultivating Long-Term Relationships During The Business Process.

Cultivating long-term mutually-beneficial relationships with customers, business partners, employees, and suppliers involved in the business process on a continuous basis. |

| 17. |

Ensuring Improvement Of All Value-Added Activities.

Ensuring steady improvement of all value-added operational activities within the organization on a continuous basis. |

|

| |

ADDITIONAL INFORMATION ONLINE |

|

|

|

|

5. VALUE-ADDED OPERATIONAL ACTIVITIES |

|

|

WHAT IS VALUE? |

Value is the worth placed upon products and services by customers.

In lean management, it's all about Value. Not just any value, but the best possible value which should be offered to customers on a continuous basis. This value must be based on the best possible quality and reliability of products and services delivered to customers at the best possible price and in a timely manner. Thus, the main objective of lean management is to identify what type of value is required, when the value needs to be improved, how the value should be added, and who will be involved and responsible for the value-added process within the organization. |

| |

WHAT IS PERCEIVED VALUE? |

Perceived Value is the value which your customers attach to your products and services. Based on lean management principles, only your customers can attach a perceived value to your products and services. Remember that:

It’s not really what you think your product or service is worth, it’s what your customers think about the value of your product or service and how they can benefit from it.

Subsequently, only your customers will decide if they are willing to pay the price which you are asking for your products or services. Moreover, since there are various operational activities involved in providing products and services, only your customers will decide which activities will actually add value and which won’t.

|

| |

VALUE-ADDED OPERATIONAL ACTIVITIES |

Every operational activity within your organization either adds value to your product or service, or doesn’t. To be considered as a Value-Added Operational Activity, it has to meet the following three requirements:

1. The customer must be willing to pay for a specific operational activity.

2. A specific operational activity must transform a product or service in a positive way.

3. A specific operational activity must be done correctly the first time around.

Here are some examples of what customers are willing to pay for and what they are not willing to pay for.

|

| |

WHAT ARE CUSTOMERS WILLING OR NOT WILLING TO PAY FOR? |

|

|

Customers Are Willing To Pay For: |

Customers Are Not Willing To Pay For: |

|

• The actual product cost.

• The actual service cost.

• The actual labor cost.

• The actual material cost.

• The actual inventory cost.

• The actual plant and equipment cost.

• The actual shipping cost.

|

• Product packaging costs.

• Marketing and selling costs.

• Indirect labor and supervision costs.

• Administration and management costs.

• Plant maintenance and repair costs.

• Business accounting costs.

• Employee hiring and training costs. |

| |

|

|

| |

DO IT RIGHT THE FIRST TIME AROUND |

| You must remember that if any operational activity is not done correctly the first time around, it will triple your cost as explained below: |

| • |

The first cost is incurred when a particular operational activity is completed the first time around. |

| • |

The second cost is incurred when a particular operational activity must be re-done because it was not done correctly the first time around. |

| • |

The third cost is incurred because if a particular operational activity would have been done correctly the first time around, you could have completed a new operational activity instead and receive an additional payment for it. |

|

| Ultimately, you and your management team must do all you can to maximize the value of your products and services offered to customers. The best way of achieving this important objective is to identify and eliminate or minimize non-value-added operational activities within your company. |

|

|

6. NON-VALUE-ADDED OPERATIONAL ACTIVITIES |

|

|

WHAT IS WASTE?

In lean management, all Non-Value-Added Operational Activities are considered as Waste and are classified as "Three M's", which are known as Muda, Mura, and Muri. It is very important that you and each member of your management team fully understand the difference between each type of waste, because it will enable you to identify, eliminate or minimize wasteful operational activities within your organization and subsequently increase your company's productivity and profitability. |

| |

THREE TYPES OF WASTE |

|

|

|

Muda |

Mura |

Muri |

Muda means “waste” in Japanese.

Muda is any non-value added operational activity that consumes resources without creating real value for a customer. There are two types of muda:

• Type 1 Muda includes any type of “non-value-added activities”, which are necessary in supporting value-added activities and should be improved, but not eliminated. This relates to essential administration, human resources, financial, operations, marketing, and sales management activities.

• Type 2 Muda includes any type of “non-value-added activities”, which are not essential and should be identified and eliminated as soon as possible. |

Mura means “unevenness” in Japanese.

Mura is any irregular or unplanned non-value-added operational activity, which should be identified, eliminated or minimized as soon as possible.

Examples of mura include product testing and inspection, redoing defected products and services, repairing returned products, incurring labor, plant and material costs for reworking previous defects, plant breakdown costs and other unscheduled working activities, unnecessary waiting for any reason within the organization or in the operational facility, conducting unproductive management meetings or unproductive meetings with employees, suppliers and customers. |

Muri means “overdoing” in Japanese.

Muri is any non-value added operational activity which causes unnecessary or unreasonable overloading of people, plant and systems within an organization and should be identified, eliminated or minimized as soon as possible.

Examples of muri include issuing wrong instructions in the workplace which will cause unnecessary waste of human, material, and financial resources, poorly designed working processes, tasks, and activities which may cause product or service defects, require additional repair work, incur unnecessary costs, and produce harmful results for customers and employees.

|

| |

|

|

|

| |

| According to lean management, there are nine basic Forms Of Waste outlined below. |

| |

NINE BASIC FORMS OF WASTE |

| 1. |

Transportation.

In a manufacturing company, transportation waste is the unnecessary movement of raw materials, work-in-process and finished goods from the supplier to the company, between various departments within the company and between the company and the customers. In a service and contracting company, transportation waste is the unnecessary movement of people and documentation between the supplier and the company, between various departments within the company and between the company and the customer. Main reasons for excessive transportation include poor supply chain design in the supplier-company-customer process, poor plant layout within the facility, and poor planning and communication within the company. |

| 2. |

Inventory.

Inventory waste represents a particularly serious problem in a manufacturing company. Main reasons for excessive inventory include poor understanding of customers’ needs and subsequent mismatch between customers’ demand and the company’s ability to supply products, excessive levels of inventory quantities, including raw materials, work-in-process, and finished goods, and ineffective inventory control. In service and contracting companies, the inventory waste is usually less problematic, but must always remain under tight control. |

| 3. |

Motion.

Motion waste is a direct result of excessive movement of people between the company and its suppliers and customers, and between various departments within the company. Motion waste also includes unnecessary delays and waiting for raw materials, work-in-process and finished goods, tools and equipment. Main reasons for excessive motion are poor planning of operational activities, unsuitable plant layout, and weak coordination of activities with suppliers and customers. |

| 4. |

Waiting.

Waiting and delays represent total waste. Main reasons for waiting and delays include poor planning of operational activities within the company, poor communication between the company and its suppliers and customers, poor communication between personnel within the company, shortage of raw materials, work-in-process, finished goods, tools, and equipment within the company, late deliveries from suppliers, and imbalance of operational activities within the company. |

| 5. |

Overproduction.

Overproduction means producing more than required. This type of waste represents a particularly serious problem in manufacturing companies and it is less of a problem in service or contracting companies. Main reasons for overproduction include poor understanding of customers’ needs and subsequent mismatch between customers’ demand and the company’s excessive production output, excessive level of plant capacity utilization, and inappropriate use of employees within the operational facility. |

| 6. |

Overprocessing.

Overprocessing means adding too much value to the finished product or service, or adding excessive value which can’t be used and will not be appreciated and paid by customers. Main reasons for overprocessing include poor understanding of customers’ needs and expectations, and subsequent mismatch between customers’ needs and the company’s ability to meet those needs without exceeding product or service cost parameters. |

| 7. |

Defects.

Defects are errors in products and services which are rejected by customers. All defects represent waste of materials, labor, plant, and operational facilities. Every time when defects occur, the cost of each defect must be tripled. The first cost of a particular defect is the wasted initial cost of materials, labor, plant, and operational facilities. The second cost of a particular defect is the cost of materials, labor, plant, and operational facilities required to re-do the specific product or service. The third cost of a particular defect is the wasted cost of another product or service which could have been completed if the initial defect wouldn’t have happened in the first place. |

| 8. |

Underutilization Of Employees.

Underutilization of employees means not using all available skills, talents, abilities, ideas, and energy of current personnel within the organization. This type of waste usually exists in organizations where business owners and managers are not able or willing to recognize that employees may possess untapped skills and desire to use these skills if given a chance. Underutilization of employees also represents a major de-motivation factor which can cause further decline in the company’s productivity and profitability. |

| 9. |

Overspending.

Overspending means spending more material, financial, and human resources than is necessary to achieve specific operational objectives. Overspending represents a total waste because excessive use of the company’s resources ultimately translates into increased operating expenses, reduced profitability and lower return on investment. Main reasons for overspending include poor management, planning and controlling skills, and abilities of the company’s management team. |

|

| |

EXAMINE ALL OPERATIONAL ACTIVITIES AND IDENTIFY WASTE |

| |

| You and your management team must examine all value-added and non-value-added operational activities and identify excessive use of material, financial, and human resources within your organization in a timely manner to ensure successful performance. You must also identify and improve all non-value added operational activities (type 1 muda) which will remain essential to your business activities, as explained next. |

| |

ESSENTIAL NON-VALUE ADDED OPERATIONAL ACTIVITIES |

| |

| Type 1 Muda includes many non-value added operational activities which may be considered "waste" in a lean organization. However, since these activities are essential in supporting the daily operation of your company, based on traditional Western-style business management principles, they should be evaluated and improved as much as possible. It is critical, therefore, that you and each member of your management team become fully familiar with relevant elements of operational management, explained in detail in this program. |

| |

IDENTIFY ESSENTIAL NON-VALUE-ADDED ACTIVITIES IN EACH OPERATIONAL AREA |

|

| |

IMPROVE YOUR CROSS-FUNCTIONAL BUSINESS KNOWLEDGE |

| |

Improved cross-functional business knowledge by each member of your management team in all operational areas will become the best guarantee for minimizing all wasteful activities and maximizing your company’s productivity, profitability, and return on investment. This knowledge is at the core of the Lean Business Engineering Method presented in this program.

You and your management team must ensure timely identification of various Type 2 Muda, Mura, and Muri non-value-added operational activities and prepare a detailed plan to eliminate or minimize waste within your organization. Subsequently, this will reduce your operational costs and enable you to offer the best product or service value to your customers and ensure your company’s profitability.

|

ADDITIONAL INFORMATION ONLINE |

|

|

|

|

7. SMALL BUSINESS EXAMPLE

VALUE-ADDED ANALYSIS |

|

|

WHAT IS VALUE-ADDED ANALYSIS? |

Does it add value or doesn’t it add value? This is the question!

According to lean management, Value-Added Analysis is a process which entails summarizing all operational activities, which relate to production of specific products and services, and determining whether each activity adds value or doesn’t add value to the final product or service. |

EXAMPLE OF VALUE-ADDED ANALYSIS |

| |

Imagine that you are hungry and you have decided to visit one of your favorite fast food places for lunch. You walk into the restaurant, wait in line for a few minutes, place your order with a friendly person behind the counter, and pay your charges. Then you sit down, wait for a while, and your meal arrives on a plate – it looks fresh, warm, and very appetizing. You enjoy your meal and, upon completion, walk out from the restaurant feeling satisfied.

Now, ask yourself what has really had to happen to provide you with a positive fast-food experience, i.e. allowing you to experience value received during this event? The answer to this question will entail summarizing each operational activity involved in this process, known as a Value Stream, and determining whether it adds value to customer’s experience or doesn’t.

Value-added analysis entails examination of each operational activity from the customers’ perspective and answering three key questions outlined below.

|

| |

VALUE-ADDED ANALYSIS SUMMARY |

|

| |

In a perfect world, you would find 30 "Yes" answers to all questions in the example above, which would indicate ideal value-added activity at a 100% level. However, in this real-world situation customers may identify 7 non-value added activities, as shown above, thereby reducing the actual value-added activity level to 77%.

When you decide to complete Value-Added Analysis related to your company's activities, you may follow the above-mentioned simple example to accomplish this task. Your analysis must include all operational activities, related to your specific products or services, taking place at your facility and you will have to determine which activities add value to your products or services and which don't. |

| |

ADDITIONAL INFORMATION ONLINE |

|

|

|

|

8. PREPARE YOUR COMPANY FOR LEAN TRANSFORMATION |

|

|

SET YOUR LEAN FOCUS

Hopefully, by now you are gradually becoming a “believer” that Lean Management can really make a big difference in your business and contribute substantially to your long-term business success.

Are you ready to increase your company’s profitability and maximize the return on your investment by transforming your business into a lean organization?

If you are ready for the Lean Transformation Process, then your company’s Lean Focus and main objective should be:

To create satisfied customers, to treat them like royalty, and to provide each customer with the best possible value of products and services, based on the highest possible quality and reliability at the best possible price.

You must remember that only your customers will decide what “the best quality” and “the best price” of products or services are. Subsequently, only they will decide whether or not to do business with you. All you can do is to maximize your efforts in earning their business and continue following lean management guidelines.

Everybody within your organization, who is directly or indirectly involved in dealing with your customers, must be well trained and prepared to treat each customer like “royalty” to secure their complete and continuous satisfaction. This superior treatment of customers must apply not only during the selling process but also extend to the after-sales services to ensure long-term customer satisfaction and loyalty toward your organization.

|

| |

ASK THE RIGHT QUESTIONS AND FOLLOW THE LEAN LOGIC SEQUENCE |

The lean transformation process follows certain logic which is applicable to various operational activities within the organization. For this reason, you and your management team should follow and implement the Lean Logic Sequence which is described by ten questions and answers, or “The Ten How’s”, outlined below. Remember, there are no wrong answers, only wrong questions. So, if you really want to succeed, you should always ask the right questions at the right time.

Note that:

• Each Question (Q) represents your specific business objective.

• Each Answer (A) provides a specific lean management guideline for your business. |

| |

THE LEAN LOGIC SEQUENCE: TEN QUESTIONS (Q.) AND ANSWERS (A.) |

|

| Q. 1: How can we maximize the profitability of our business? |

|

| A. 1: By achieving the best possible operational and financial results through our business activities. |

|

|

| Q. 2: How can we achieve the best possible operational and financial results through our business activities? |

|

| A. 2: By providing our customers with the utmost respect on a continuous basis and the best possible value of products and services in a timely manner. |

|

|

| Q. 3: How can we provide our customers with utmost respect on a continuous basis? |

|

| A. 3: By introducing lean culture within our organization and implementing effective lean training of our employees. |

|

|

| Q. 4: How can we introduce lean culture within our organization and implement effective lean training of our employees? |

|

| A. 4: By evaluating our current values and organizational culture, employee performance and training methods, and implementing lean management and employee training guidelines. |

|

|

Q. 5: How can we provide our customers with the best possible value of products

and services? |

|

A. 5: By offering our customers the best possible quality of products and

services at the best possible prices and after-sales service. |

|

|

Q. 6: How can we offer our customers the best possible quality of products and

services at the best possible prices and after-sales service? |

|

| A. 6: By developing and implementing operational plans (hoshin planning), streamlining all operational activities, maximizing operational efficiency through improved value-added activities and eliminating or minimizing non-value added activities and waste within our organization. |

|

|

| Q. 7: How can we implement our operational plans, streamline our operational activities, maximize our operational efficiency, and minimize waste? |

|

| A. 7: By evaluating and improving all current operational activities related to each product or service category within our organization through value-stream mapping (VSM). |

|

|

| Q. 8: How can we evaluate and improve current operational activities within our organization through value-stream mapping (VSM)? |

|

| A. 8: |

By identifying and summarizing all value-added and non-value-added operational activities, conducting value-stream analysis and developing improved value-stream maps, conducting kaizen events, and implementing improved flow processes based on just-in-time, jidoka, and total preventive maintenance guidelines within our organization. |

|

|

| Q. 9: How can we provide the best possible value of products and services to our customers in a timely manner? |

|

| A. 9: By implementing improved flow processes based on kaizen, just-in-time, jidoka and total

preventive maintenance guidelines within our organization. |

|

|

| Q. 10: How can we ensure short- and long-term improvement of our company's operational performance and financial results? |

|

A. 10: By adhering to all lean management methods and guidelines within our organization on

a continuous basis as described above. |

|

|

| |

LEAN TRANSFORMATION IS A NEVER-ENDING JOURNEY |

| |

Lean transformation is not a sprint. It is a marathon!

You and each member of your management team must realize that Lean Transformation is not a specific destination, but a never-ending long-term journey. You must begin this journey at a starting point, which is represented by your company’s current situation, and be prepared to continue your journey into the future on a step-by-step basis. The key to your company’s lean transformation success will be:

The total commitment to lean management principles, methods, and guidelines by you and each member of your management team.

Through your lean journey you will discover several important management methods, called Lean Management Methods, outlined below. |

| |

BASIC LEAN MANAGEMENT METHODS |

|

| |

| Each lean management method is discussed in detail in this check point. |

| |

ADDITIONAL INFORMATION ONLINE |

|

|

|

|

9. BASIC TASKS IN THE LEAN TRANSFORMATION PROCESS |

|

|

FAMILIARIZE WITH THE LEAN TRANSFORMATION PROCESS |

| |

You and each member of your management team should become familiar with the Lean Transformation Process designed to transform your company from its' current state into a new and improved lean state. The main purpose of this process is to enable you and your management team to take a step-by-step approach toward meeting your specific business objectives.

Lean transformation process entails completing several important steps outlined below. |

| |

BASIC STEPS IN THE LEAN TRANSFORMATION PROCESS |

|

| 1. Adopt Basic Lean Management Guidelines In Your Company. |

|

| 2. Make Lean A Part Of Your Company's Organizational Culture. |

|

| 3. Create A Lean Management Team And Develop Lean Team Managers. |

|

| 4. Identify What Your Customers Want And Develop Your Best Value Proposition. |

|

| 5. Develop And Implement Hoshin Planning In Your Company. |

|

| 6. Develop And Implement Cross-Functional Operational Plans In Your Company. |

|

| 7. Complete Value-Stream Mapping And Value-Added Analysis In Your Company. |

|

| 8. Implement The Improved Value Stream In Your Company. |

|

| 9. Repeat The Lean Transformation Process As Required. |

|

| |

ADDITIONAL INFORMATION ONLINE |

|

|

|

|

10. ADOPT BASIC LEAN MANAGEMENT GUIDELINES IN YOUR COMPANY |

|

|

BASIC LEAN MANAGEMENT GUIDELINES

Lean transformation process requires that you and each member of your management team study and adopt Basic Lean Management Guidelines outlined below.

|

| |

TASK 1: ADOPT BASIC LEAN MANAGEMENT GUIDELINES IN YOUR COMPANY |

| 1. |

Be Open-Minded, Self-Critical, And Prepared For A Change.

Be completely open-minded and self-critical regarding your personal behavior and your company’s business activities and prepared for a change to improve your business performance. |

| 2. |

Identify Operational Inefficiencies And Waste.

Identify and evaluate operational inefficiencies and wasteful processes and activities related to your company’s products and services. |

| 3. |

Prepare A Plan Of Action To Minimize Inefficiencies And Waste.

Develop a plan of action to improve operational processes and activities related to your company’s products and services. |

| 4. |

Improve Operational Processes And Activities.

Implement your plan of action to improve operational processes and minimize wasteful activities related to your company’s products and services on a continuous basis. |

| 5. |

Ensure Employee Participation.

Motivate every employee to maximize personal performance and participate in improving operational processes and activities within your organization. |

| 6. |

Ensure That Your Customers Are Treated Like Royalty.

Motivate every employee to treat each customer as the most important person within your organization. |

| 7. |

Offer Your Customers The Best Possible Value.

Ensure that all customers receive best possible products and services at best possible prices and after-sales service from your organization. |

| 8. |

Ensure That Your Employees Are Treated With Genuine Respect.

Ensure that every employee within your organization is treated with genuine dignity, care, and respect. |

| 9. |

Ensure Maximum Safety Of Your Customers And Employees.

Ensure that maximum safety is provided to all your customers and employees within your organization. |

| 10. |

Develop And Implement Hoshin Strategic And Operational Planning.

Develop and implement hoshin strategic and operational planning designed to maximize your organization’s performance, productivity, profitability and return on investment. |

| 11. |

Implement Kaizen Guidelines.

Implement kaizen guidelines to relevant operational activities within your organization designed to improve performance of all employees and quality of all products and services for your customers. |

| 12. |

Implement Just-In-Time Guidelines.

Implement just-in-time guidelines to relevant operational activities within your organization to ensure the best possible value of products and services for your customers. |

| 13. |

Implement Jidoka (Autonomation) Guidelines.

Implement jidoka (autonomation) guidelines to relevant operational activities within your organization. |

| 14. |

Implement Total Productive Maintenance (TPM) Guidelines.

Implement total productive maintenance (TPM) guidelines to relevant operational activities within your organization. |

| 15. |

Plan And Implement Value-Added Activities.

Plan and implement value-added activities designed to ensure the best possible value of products and services for your customers. |

| 16. |

Plan And Implement A Continuous Flow Based On A “Pull” Sequence.

Develop a continuous flow of processes and activities within your organization based on a “pull” operational sequence. |

| 17. |

Plan And Implement Standardized Operational Processes And Activities.

Simplify and standardize all operational processes and activities related to products and services within your organization. |

| 18. |

Plan And Implement Highest Level Of Quality At The Source.

Ensure highest possible quality at the source of all operational processes and activities related to products and services within your organization. |

| 19. |

Plan And Implement Effective Cross-Functional Communication.

Ensure clear, continuous, and cross-functional communication between all employees within your organization. |

| 20. |

Promote Individual Growth And Knowledge Improvement.

Ensure individual growth and knowledge improvement by all employees within your organization on a continuous basis. |

| 21. |

Challenge And Motivate All Employees.

Challenge and motivate all employees to continue effective implementation of all lean management guidelines within your organization. |

| 22. |

Create A Blame-Free Working Environment.

Motivate all employees to think “outside-the-box” and express their creativity in improving various operational processes and activities without being afraid that they may be blamed for any potential negative consequences. |

| 23. |

Never Rest On Your Laurels.

Ensure that employees in your organization never settle for what has been achieved so far, and understand that lean process and continuous improvement are not a destination, but a journey designed to make your company more successful by doing the “right things” for your customers and employees. |

|

| |

ADDITIONAL INFORMATION ONLINE |

|

|

|

|

11. MAKE LEAN A PART OF YOUR COMPANY'S ORGANIZATIONAL CULTURE |

|

|

TASK 2: MAKE LEAN A PART OF YOUR COMPANY'S ORGANIZATIONAL CULTURE |

Lean Transformation Process entails:

1. Evaluating your company’s current Organizational Culture.

2. Examining the basic values which guide you and your management team.

3. Improving the organizational culture according to lean management guidelines.

Every organization is unique in many different ways and your company is not an exception. For this reason, it is critical that you and your management team “take stock” of the organizational culture which currently exist in your company. This process entails answering questions which relate to your personal core values and your company’s basic principles and priorities.

|

DECIDE WHAT IS REALLY IMPORTANT TO YOU |

|

|

Is This Most Important To You? |

Or, Is This Most important To You? |

•

|

- To make as much money for our company as possible in the shortest period of time.

|

|

•

•

•

•

•

|

- To provide our customers with the best possible value of products and services in a profitable manner.

- To ensure our customers' satisfaction while maintaining long-term profitable performance.

- To ensure our customers' and employees' safety while maintaining long-term profitable performance.

- To maintain strong reputation in the marketplace while maintaining long-term profitable performance.

- To maintain high moral code in relation to customers, suppliers, and employees, while maintaining long-term profitable performance.

|

|

|

| |

EVALUATE THE LEVEL OF YOUR MANAGERIAL ETHICS |

| |

You and your management team should also evaluate the level of Managerial Ethics which currently exists in your organization. Some business owners erroneously believe that short-term profits are the most important part of their business and everything else fails in comparison. They are often willing to cut corners to achieve their goals, employing questionable business ethics, and placing their personal interests above everything else. These business owners fail to realize that decency and honesty are actually the best long-term business policies.

On the other hand, there are many successful business owners, who conduct their business based on high moral code level. These business owners adhere to management principles and core values, based on decency and genuine caring for customers and employees, even if at times it may not be so profitable in the short term.

You and your management team are strongly advised to adopt Lean Values and make them an integral part of your organization.

Organizational Culture and Managerial Ethics are discussed in detail in Tutorial 1. |

| |

ADDITIONAL INFORMATION ONLINE |

|

|

|

|

12. CREATE A LEAN MANAGEMENT TEAM AND DEVELOP LEAN TEAM MANAGERS |

|

|

TASK 3: CREATE A LEAN MANAGEMENT TEAM AND DEVELOP LEAN TEAM MANAGERS

|

| |

Lean transformation process requires a creation of an efficient Lean Management Team, or Lean Team, within your organization. In fact, the success or failure in transforming your business into a lean organization depends primarily upon your ability to create an efficient and cohesive lean team of managers and employees who will work together toward achieving common lean objectives.

The ultimate success of your lean team will depend substantially upon the characteristics, values, and experience of the Lean Team Manager. For this reason it is critical to ensure that each lean team manager within your organization possesses specific characteristics, which will enable your company to achieve desired results in the most cost-efficient manner. Some of these characteristics are summarized below. |

| |

CHARACTERISTICS OF A LEAN TEAM MANAGER |

| 1. |

A Thorough Understanding Of Lean Management Values, Principles, And Guidelines.

A lean team manager must be prepared to learn and understand a broad range of lean management values, principles, methods, guidelines, and tools. |

| 2. |

Total Commitment To Implement Lean Management Principles And Guidelines.

A lean team manager must be totally committed to the implementation of lean management principles and guidelines within the organization on an individual and team-level basis. |

| 3. |

Strong Analytical Ability To Evaluate Current Situation Within The Organization.

A lean team manager must possess a strong analytical ability to evaluate current situation and quickly identify specific problems and inefficiencies related to various operational processes and activities within the organization. |

| 4. |

Total Commitment To A Continuous Improvement Of Processes And Activities.

A lean team manager must be totally committed to a continuous improvement of operational processes and activities, based on kaizen principles and guidelines, within the organization. |

| 5. |

Strong Commitment To Maximize Quality Throughout The Organization.

A lean team manager must be totally committed to maximize quality of products and services through improved quality of all operational processes and activities within the organization. |

| 6. |

Total Commitment To Identify And Eliminate Wasteful Activities.

A lean team manager must be totally committed to identify, eliminate or minimize wasteful processes and activities within the organization through continuous value-added analysis. |

| 7. |

Strong Ability To Demonstrate Flexibility, Innovation, And Adaptability.

A lean team manager must demonstrate and promote flexibility, innovation and adaptability to all members of the lean management team throughout the entire lean transformation process. |

| 8. |

Strong Ability To Develop Cost-Effective Solutions On Organization-Wide Basis.

A lean team manager must provide sound and practical approach to resolving existing operational problems and developing new cost-effective solutions within the organization. |

| 9. |

Total Commitment To Deliver Maximum Value To Customers.

A lean team manager must be totally committed to provide maximum value to customers through best possible quality and prices of products and services and best possible after-sales service. |

| 10. |

Strong Commitment To Hire High Quality Employees.

A lean team manager must be able to identify and hire suitable employees who will be willing and able to follow lean management principles and guidelines on a continuous basis. |

| 11. |

Total Commitment To Effective Lean Management Training Of Employees.

A lean team manager must be totally committed to provide effective individual and team training to all employees in various areas of lean management to secure cost-effective operational results within the organization. |

| 12. |

Strong Ability To Provide Clear Purpose And Direction To Each Team Member.

A lean team manager must possess effective leadership skills and provide clear purpose and guidance to each team member to secure most effective results within the organization. |

| 13. |

Strong Ability To Respect, Reward, And Compensate Employees.

A lean team manager must be able to demonstrate strong respect and be prepared to reward and fairly compensate employees according to their performance and contribution toward meeting the company’s objectives. |

| 14. |

Total Commitment To All-Around Safety Within The Organization.

A lean team manager must be totally committed to ensure all-around safety concerning all customers and employees and related to all operational processes and activities throughout the organization on a continuous basis. |

| 15. |

Strong Ability To Communicate Effectively On A Cross-Functional Basis.

A lean team manager must be able to communicate clearly and effectively on a cross-functional basis with all team members to secure effective implementation of lean management solutions within the organization. |

| 16. |

Continuous Focus On Improved Processes, Activities, And Results.

A lean team manager must be able to focus on improving all operational processes, activities and specific operational results achieved by the organization on a continuous basis. |

| 17. |

Strong Ability To Be Open-Minded And Self-Critical.

A lean team manager must be open-minded during the process of evaluating current situation, planning and implementing new operational solutions, and self-critical in evaluating accomplished results within the organization. |

| 18. |

Strong Ability To Build Long-Term Relationships With Suppliers And Customers.

A lean team manager must be able to develop mutually beneficial long-term relationships with suppliers and customers on individual basis to secure the most productive organizational performance. |

| 19. |

Never Be Satisfied With Accomplished Results.

A lean team manager must “never rest on his/her laurels” and be always focused and highly motivated to make further improvements related to all operational processes and activities within the organization. |

| 20. |

Strong Ability To Create A Blame-Free Working Environment.

A lean team manager must be able to develop and cultivate a “blame-free” environment and identify specific operational problems without trying to assign blame to a particular employee, thereby motivating employees to think “outside-the-box” and develop new solutions without any reservations. |

| 21. |

Total Commitment To High Moral Values.

A lean team manager must be totally committed to implementing and maintaining high ethical standards by all employees throughout various operational processes and activities within the organization on a continuous basis. |

| 22. |

Total Commitment To “Politics-Free”

Working Environment.

A lean team manager must be totally committed to identify and eliminate any trace of “destructive political behavior” and “inter-office manipulations” and ensure a healthy and “politics-free” working environment within the organization. |

|

| |

| You may also want to read The Lean Manager authored by Michael Balle and Freddy Balle and published by the Lean Enterprise Institute. |

| |

ADDITIONAL INFORMATION ONLINE |

|

|

|

|

13. IDENTIFY WHAT YOUR CUSTOMERS WANT AND DEVELOP YOUR BEST VALUE PROPOSITION |

|

|

TASK 4: IDENTIFY WHAT YOUR CUSTOMERS WANT

AND DEVELOP YOUR BEST VALUE PROPOSITION |

If you ask a typical business owner: “What is your most important business goal?”, you will probably get this answer: “To make as much money as I can as quickly as possible!”. This may be interpreted as: “It is all about me, my business, my profits, and my return on investment!”

The truth is that it’s not just about you! It’s really about your opportunity to identify your customers’ specific needs and provide them with timely and cost-effective solutions and as a result to be rewarded in a profitable way. The bottom line:

This is about creating a win-win situation between your customers and you!

There is nothing wrong in “making money”! In fact, you do need money to survive in business. However, the problem is that some unscrupulous business owners try to “make quick profits” by cutting corners and using ethically-questionable practices to achieve their goals. One of the main objectives of the entire Lean Business 2100 Management Program is to show you how you can “make money in an honest way” and adoption of lean management principles and guidelines will be critical in achieving this goal. Remember that:

At the end of the day you are answerable to only one person – you see this person in the mirror every day!

For this reason, re-assure yourself, that only through solid values, based on honesty, genuine care, and respect for others, you will achieve your personal and business objectives and remain successful in the long term! |

CRITICAL PRINCIPLE OF LEAN MANAGEMENT |

| |

You and each member of your management team should always remember one of the most critical principles of lean management:

Treat your customers like royalty and earn their loyalty!

You are strongly advised to embrace this principle and start treating all your customers like “royalty”. You and your management team must be prepared to do whatever you can to identify and satisfy your customers’ specific needs in a timely manner and your success will follow.

You must also make sure that everybody in your organization adopts this principle as soon as possible. This will enhance your company’s ability to provide your customers with the Best Possible Value of products and services on a continuous basis. As a result, you will be rewarded by an increased level of customers’ appreciation and long-term loyalty toward your organization. Ultimately, your company will be rewarded with an increased level of sales, profitability and return on investment.

Your customers are people, just like you, who have needs and wants and would like to solve their specific problems by using reliable products or services at reasonable prices. You must be able to identify your customers’ problems well in advance and view these problems as your opportunity to satisfy their needs, while achieving your business objectives. Once you adopt this critical business principle, you will improve your chances of developing a long-term mutually beneficial relationship with your customers and this could become the cornerstone of your business success in the future.

|

| |

IT'S ALL ABOUT VALUE |

| |

Many business owners erroneously assume that price is one of the most critical factors why customers decide to buy specific products and services. The truth, however, is that:

It is not about the price, it’s all about the value offered to customers!

Just ask anybody who purchased a Japanese-made product and was prepared to pay more instead of paying less and taking chances. For this reason, you and your management team must understand what really is Value related to your products or services and how your customers perceive this value. You must also remember that:

• “You really get what you pay for!”

• “If it is too good to be true, it probably is!”

|

| |

WHAT DOES VALUE REALLY MEAN? |

You should always keep in mind that many savvy customers today, just like you, usually know what is in their best interests when making purchasing decisions. Moreover, you must remember that your customers alone will decide what “value” really means to them and all you can do is to maximize your efforts in offering your customers the best possible value on a continuous basis.

Value is a relative concept and it may mean many different things to different customers. For example, it may include the following:

• Ability to meet the customer’s specific needs.

• Price and available discounts.

• Quality and reliability.

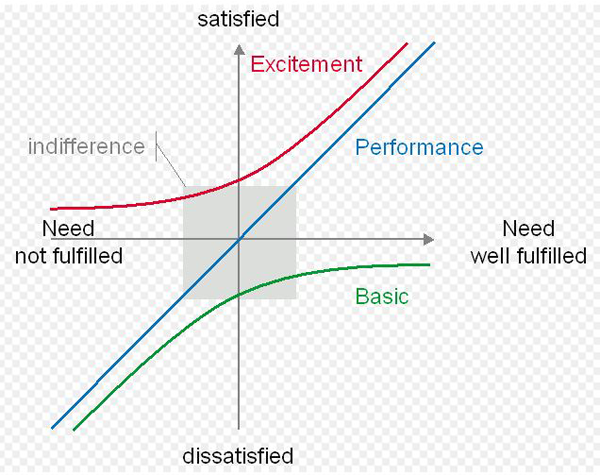

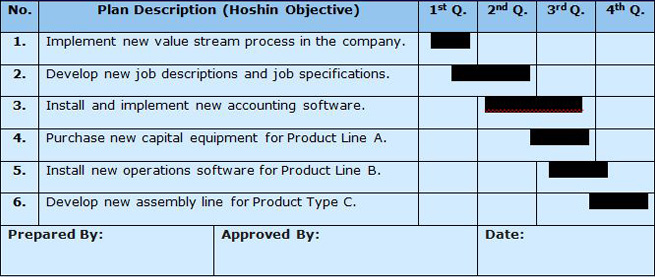

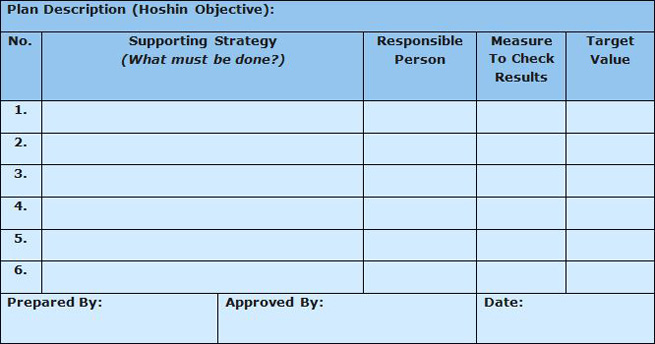

• Timing, availability, and location.